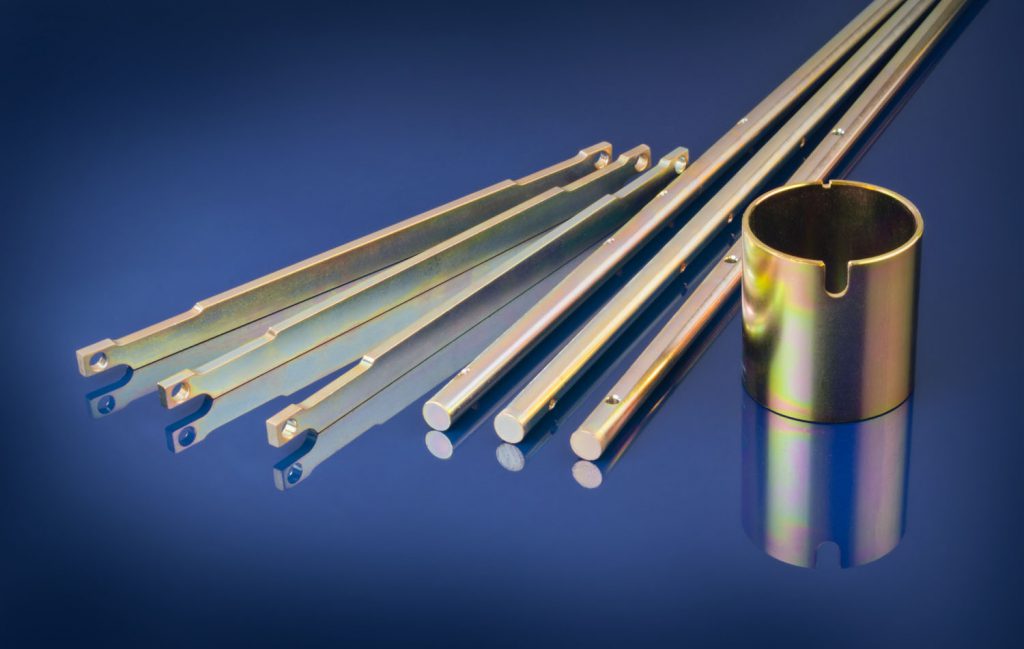

Precision Fabricating

PJ Tube’s precision fabricating services provide customers with access to a wide variety of options to meet their unique specifications on time and on budget.

Precision Fabricating Services

Capabilities

- Bending – finished made-to-spec tubing for customer-specific applications

- Drilling and piercing – preparing tubing to be connected to other components

- Finning – improves heat transfer efficiency

- Flattening – used for connecting parts

- Grinding – improves surface finish and removes metal to meet tolerance specifications

- Honing – achieves precise ID diameter dimensions

- Notching, coping, and saddle cutting – used when making parts that need to fit together

- Swaging – reduces the diameter of tubes to fit into a mating part

- Heat treating – changes the mechanical properties of the tube to meet application critical requirements

- And MORE

Industries Served

-

Available services include:

- Bending services provide finished made-to-spec tubing for applications in a wide range of industries.

- Drilling/Piercing is used for applications that require mating parts, preparation for threading, drain holes, and connecting parts.

- Expanding, reducing, and flaring are employed when tubing needs to be connected to other components.

- Finning improves heat transfer efficiency by increasing the surface area of the tubing available for heat transfer. Sample applications include heat exchangers.

- Flattening is used for connecting parts. Applications often involve joining pieces in an assembly.

- Grinding improves surface RMS finish and removes metal to meet critical tolerance specifications.

- Honing is performed to achieve precise ID diameter dimensions. Sample applications include hydraulic cylinders.

- Notching, coping, and saddle cutting are used when making parts that need to fit together. For example, cuts in a tube to secure one tube to another without a gap. Sample applications include frame tubes.

- Swaging reduces the diameter of tubes to fit into a mating part.

- Heat Treating is used to change the mechanical properties (for example to increase/decrease ductility or increase/decrease hardness) of the tube to meet application critical requirements.

-

Applications

Customers depend on P&J Tube end finishing capabilities for a wide variety of needs, including but not limited to applications in the following markets and niches:

- Agricultural

- Automotive

- Consumer Products

- Defense and Ordinance

- Durable Medical

- Food & Beverage

- Heavy Truck

- HVAC

- Industrial

- Mining

- Oil & Gas

- Power Sports

- Others

-

Inquiry

If your products require precision fabricating services, we provide all of the options that you need within one company, minimizing scheduling problems and eliminating many other risks associated with managing multiple vendors that could threaten your projects success. We deliver your product, made-to-spec, when you need it most! For further details about capabilities and value-add services, please contact us at salesdept@pjtube.com or phone 1-877-411-TUBE.