Precision Cutting + End Finishing

PJ Tube’s precision cutting and end finishing capabilities provide our customers with custom fabrication solutions to meet their unique specifications, on time and on budget – every time.

00:00

00:00

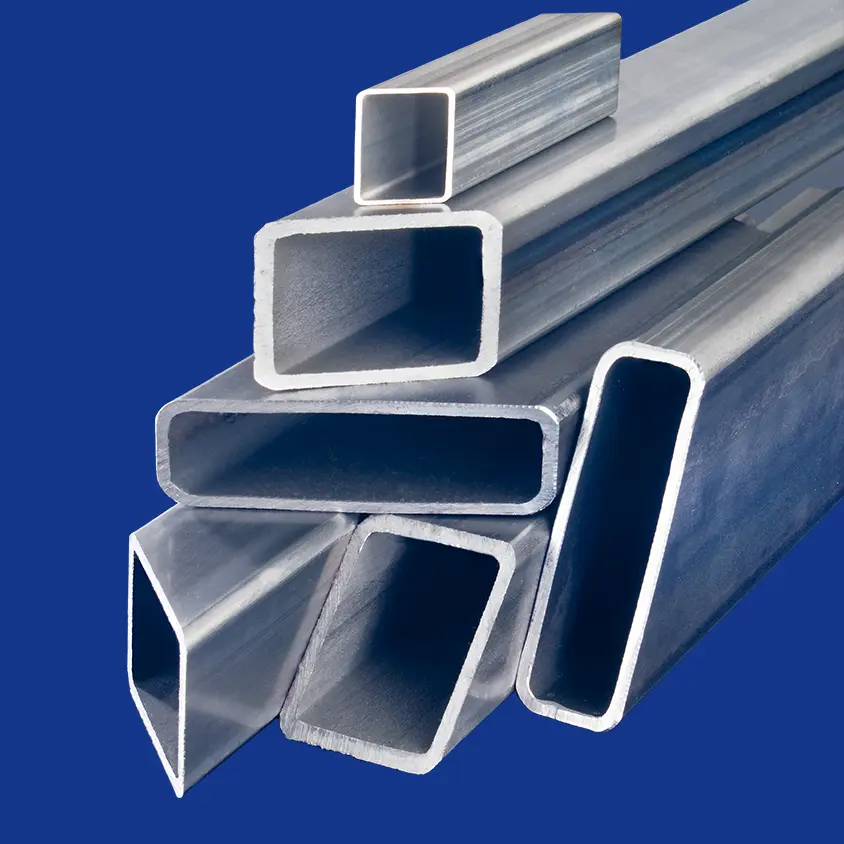

PJ Tube precision cuts ferrous and non-ferrous materials, including aluminum, carbon steel, copper, nickel alloys, stainless steels, titanium as well as specialty alloys in rounds, squares, oval, rectangular and other unique shapes.

Precision Cutting Service

Our innovative solutions and cutting-edge technology provide precision cut-to-length tubing, brush deburring, mitre cutting, chamfering and facing, and MORE.

Capabilities

- Rattunde tube and bar cutting technology

Cut-and-brush plus cut-and-chamfer machines - Tight tolerances

+/- 0.003” or better - OD/ID grooving and OD/ID threading

- And MORE

Precision End Finishing

Working with a single company that can manufacture your product from start to finish provides you with built-in quality assurance and scheduling advantages that keep your projects on track.

Available Services Include

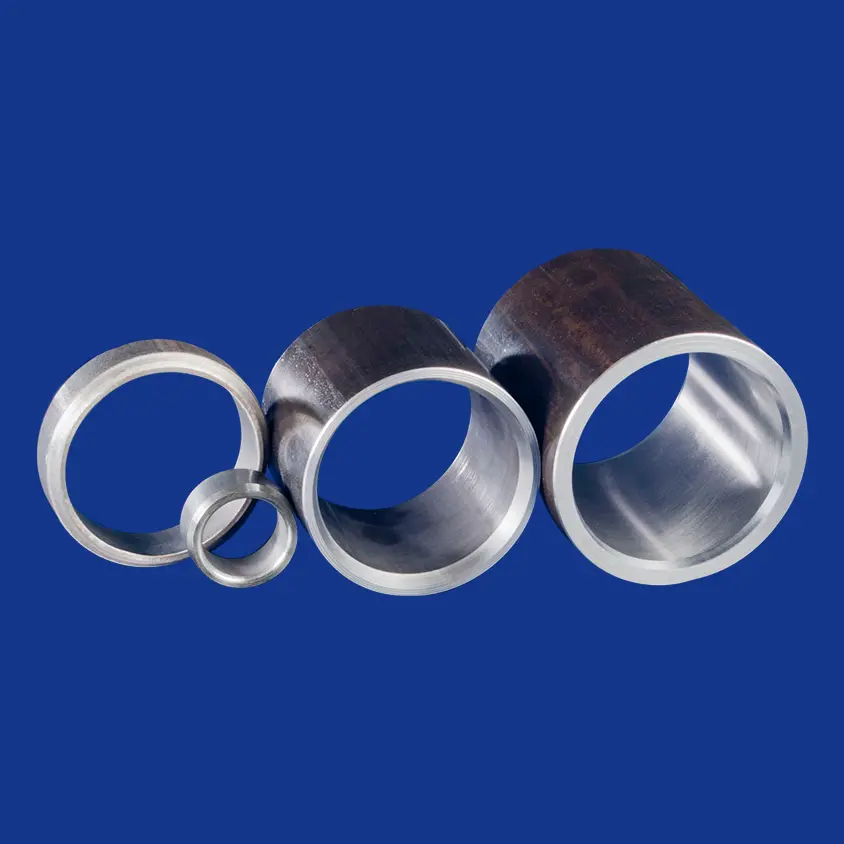

- Chamfering

Sample applications: suspension bushings, shock bushings, and eyelet bushings for hydraulic cylinders - Brush/Deburring/Tumbling

Sample applications: esthetics, mating parts - ID/OD Grooving and Threading

Sample applications: securing an o-ring for better sealing